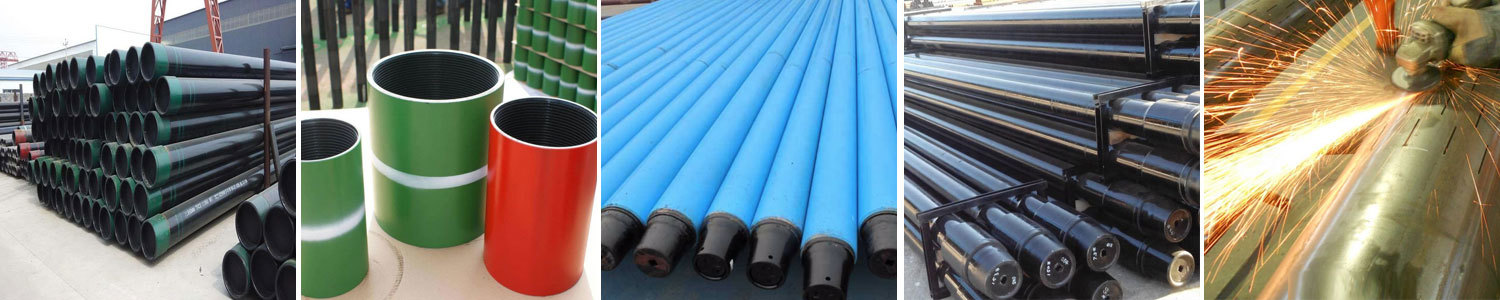

- Commodity name: Casing And Tubing Coupling

Casing And Tubing Coupling

Keyword:

Casing And Tubing Coupling

Related Products

Description

About Tubing coupling

Normally tubing coupling OD maximum is 4 1/2”, as the tubing pipe is applied for the drilling activities (Inside the tubing is the sucker rod to drill/pump the oil), couplings type is more various and rigorous than casing, mostly used is thicken type upset coupling (Internal upset and external upset), for short is EUE coupling, it is the most favorable in tubing connections. Tubing with EU end (EUE) coupling connection also called UPTBG. Because of the end of the tubing is thickened (upset), the connecting stress is better than buttress coupling.

Buttress coupling another type used for tubing connections, it has the same thickness of the pipe body, called NU end (NUE)tubing or TBG.

Features

The oil tubing coupling can solve the problem of fatigue fracture in the existing coupling due to stress concentration. Oil tubing end is connected to the inside wall of the coupling in a tapered thread. The coupling body end and oil tubing are connected with same thread pitch flat thread. The coupling is not easy to produce fatigue fracture, and has good connection effect. It can prevent the accident of oil well pipe string break effectively.

About Casing coupling

Casing coupling is for the dimensions more than 4 1/2 inch. Differently than tubing coupling is, casing coupling normally does not need to be thickened (Non-upset), which means no upset casing coupling, so it has following types:

• BTC: Buttress coupling

• LTC: Long buttress coupling

• STC: Short buttress coupling

All three types has same thickness of the casing pipe body, just have different lengths.

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

Seamless and ERW Casing

Specification | API 5CT |

Grades | K55, N80, L80, C95, P110, Chrome, J55(Modified), J55 (API), PS80 |

Special Grades | For sour services and for deep well with high collapse properties |

Dimensions | OD 4" - 26" WT - 0.2 -0.5" |

Length range | 1, 2 or 3 |

Thread connections | API (STC and LTC), BTC, extreme line, etc. |

Seamless and ERW Tubing

Specification | API 5CT |

Grades | J55 (API) J55(Modified), N80, L80, L80 13Cr, P110, Q125, H40 (API) |

Thread connections | API 5B - Last Edition or Premium, EUE, NUE, special seal, metal-to-metal seal and VAGT |

Specification

Casing Couplings Short Thread Specifications:

Casing Couplings | Casing Size OD (inches) | Coupling Size OD (inches) | Length (inches) | Weight per Coupling (lbs) | Palletized Carton Quantity |

| 4-1/2 | 5.000 | 6.250 | 8.05 | 343 |

Packing And Delivery

Located in the Free Trade Pilot Zone of Jinan City, Shandong Province, close to Tianjin Port and Qingdao Port, China's famous ports, it has a superior production and operation environment, convenient logistics exports, mature industrial facilities, and complete supporting industries.

Honor

Quality-oriented, constantly achieve product optimization, to create high-quality steel, is our constant pursuit. The products have passed the national security 3C certification, EU CE certification and ISO9001 international quality system certification.

Factory

The company is equipped with a complete product production line. Cutting machines, bending machines, punches, water jet cutting machines, polishing machines, shearing machines, wire drawing machines and other professional equipment are complete.

Customer visit

Get A Quote

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products